Maintaining panel furniture is essential to ensure its longevity and appearance. Here are some key tips to help you care for your furniture properly:

Proper Placement

Ensure the surface where your panel furniture is placed is flat and even. Uneven floors can cause instability, leading to wobbling or even structural damage over time. If the floor is uneven, avoid using wooden boards or metal sheets under the legs, as they may not distribute weight evenly. Instead, consider leveling the floor or placing a thick rubber mat beneath the furniture to keep it stable and prevent internal damage.

Dust Removal

Regularly dust your furniture with a soft, clean cloth made of pure cotton. For detailed patterns or embossed surfaces, use a soft wool brush to gently remove dust without scratching the finish. Avoid using harsh chemicals like gasoline or solvents on painted surfaces. A colorless furniture polish can help maintain shine and reduce dust accumulation.

Avoid Direct Sunlight

Keep your furniture away from direct sunlight. Prolonged exposure can cause paint to fade, metal parts to oxidize, and wood to become brittle. In summer, use curtains or blinds to protect your furniture from intense sun rays and maintain its condition.

Maintain Indoor Humidity

Control indoor humidity levels to avoid excessive moisture. Too much humidity can lead to wood swelling, metal rusting, and adhesive joints loosening. Use humidifiers sparingly in dry seasons and avoid using alkaline water when cleaning. Always wipe with a slightly damp cloth and then dry it with a clean, dry cloth to prevent moisture damage.

By following these simple yet effective maintenance steps, you can significantly extend the life of your panel furniture and keep it looking great for years to come.

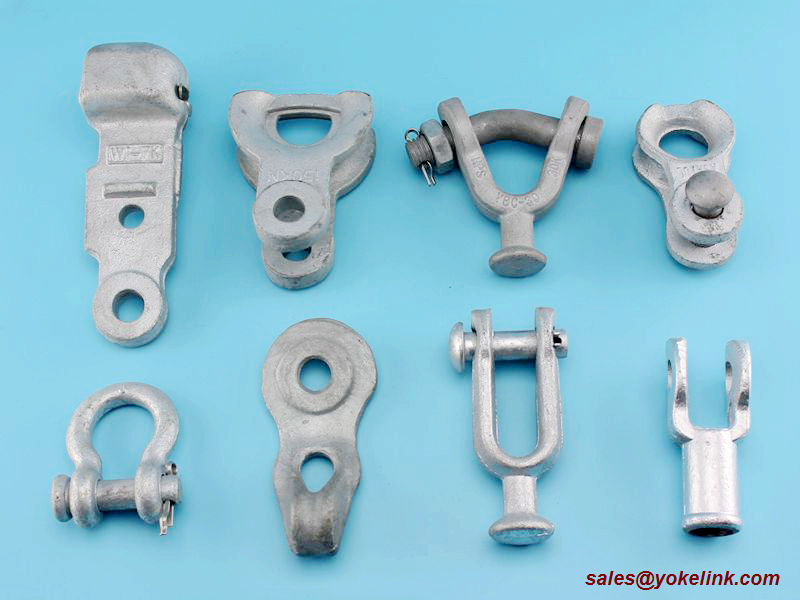

Transmission hardware fittings are components used in the construction and maintenance of transmission lines for electricity or telecommunications. These fittings are designed to connect, support, and secure the different parts of the transmission line, ensuring proper functioning and reliability.

Some common types of transmission hardware fittings include:

Suspension Clamps: Used to hang the conductors from the transmission towers, providing support and preventing sagging.

Dead-end Clamps: Used to terminate the conductors at the ends of the transmission line, providing support and preventing them from slipping.

Splice Sleeves: Used to join two conductors together, ensuring a secure and conductive connection.

Insulators: Used to electrically isolate the conductors from the transmission towers, preventing electrical leakage and ensuring proper insulation.

Guy Wire Fittings: Used to secure and stabilize the transmission towers, preventing them from swaying or collapsing.

Connectors: Used to connect different components of the transmission line, such as conductors, insulators, and fittings, ensuring a secure and reliable connection.

Yokelink supply a full line of Tower hardwares, , provide part number to get a quote on these products, leave your message, or send us an email to get answers for your questions or product you needed.

Socket Eyes are used for connecting conductor clamping devices to ball and socket type insulators. Made by malleable iron, hot dip galvanized to meet ASTM A153 specification.

Ball Eyes are used to attach ball and socket insulators to other associated hardware. Hot dip galvanized to meet ASTM A153 specification.

Thimble Cleivs are used for attaching guy to pole eye plate. Hot dip galvanized to meet ASTM A153 specification.

Turnbuckles are used as adjustable extension links to maintain proper tower clearance on assemblies at tower end.

Strain Clamp used for distribution and transmission line construction with all aluminum ACSR, or aluminum alloy conductor.

Transmission Hardware Fitting, Socket,Ball eye, Hot line, Chain Link, Turnbuckle, Suspension, Strain, Yoke plate,malleable iron,hardware,tower,links

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com